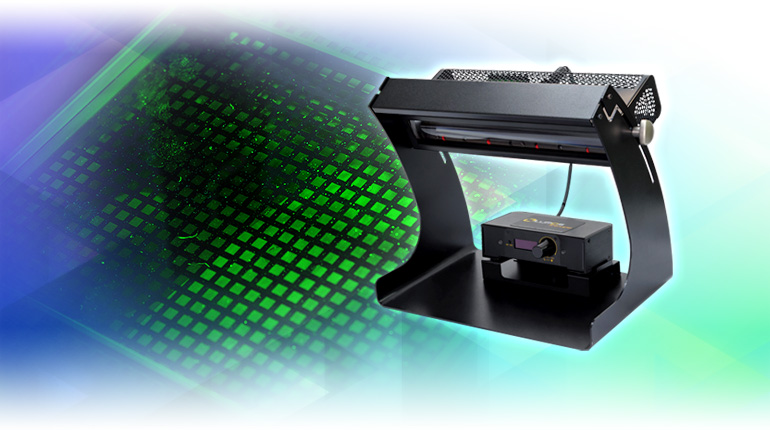

Inspection Task Lighting (Dust detection light)

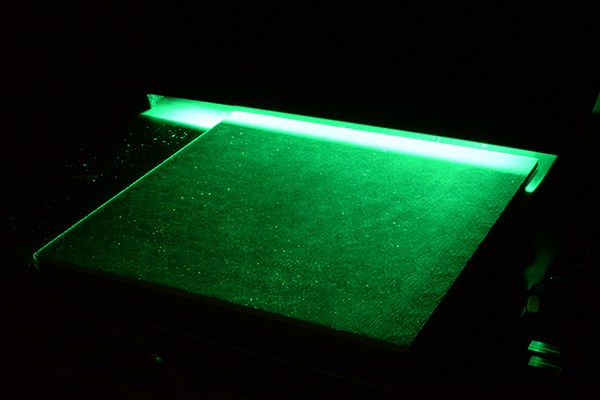

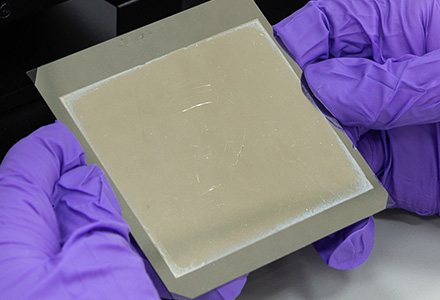

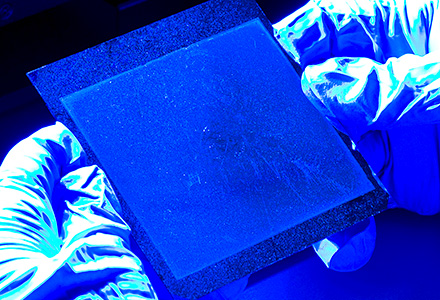

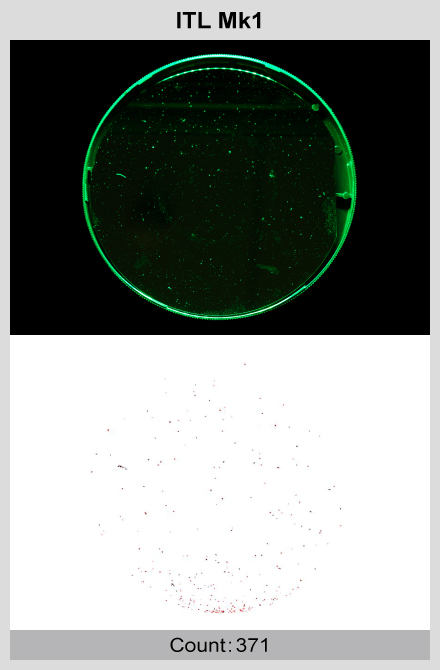

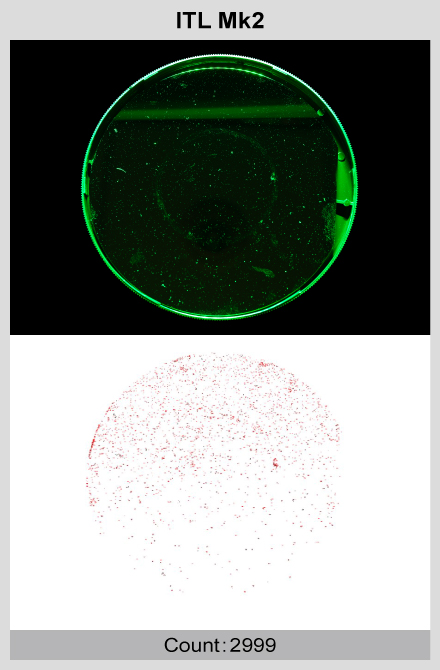

Note: The sample wafer has 300+ dust particles visible under Mk1 and 3000+ dust particles under Mk2.

(comparison image)

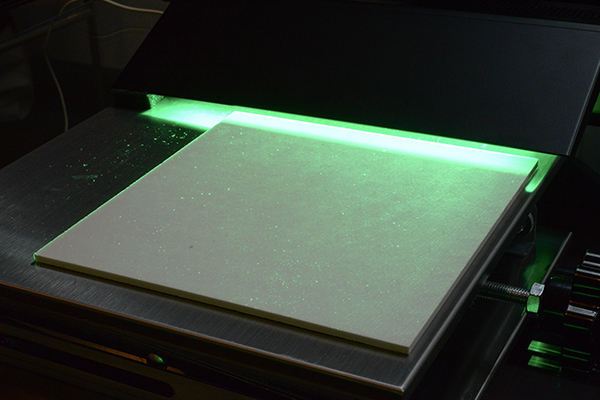

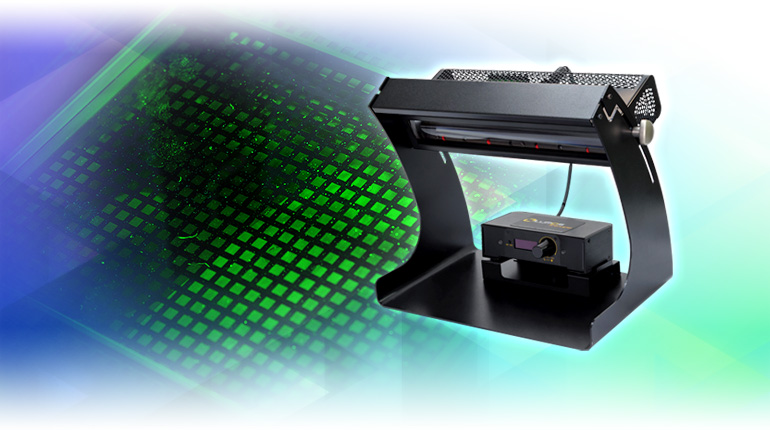

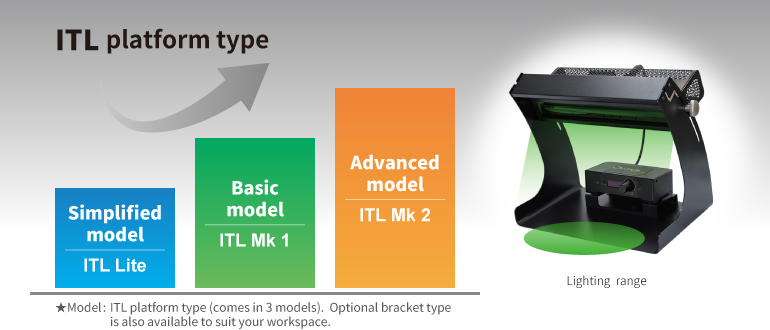

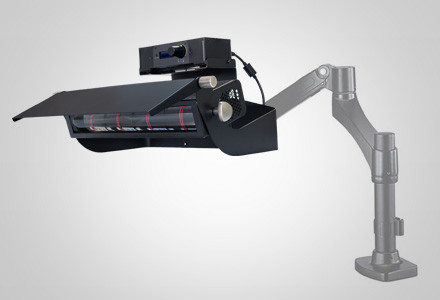

The Platform-type (all models) light box can be independently paired with a cantilever bracket luminaire; ideal for large areas requiring consistent, even lighting.

Understanding and responding to customer needs: From MK1 to MK2, we have continuously improved to meet the specific needs of the semiconductor industry, pharmaceutical plants and fine printing companies, as well as other customers who use clean rooms.

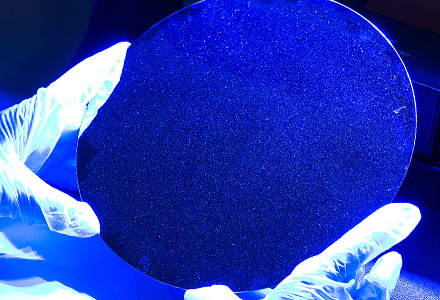

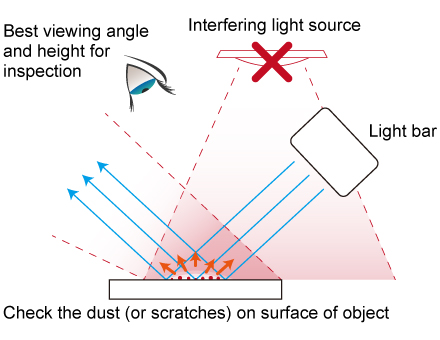

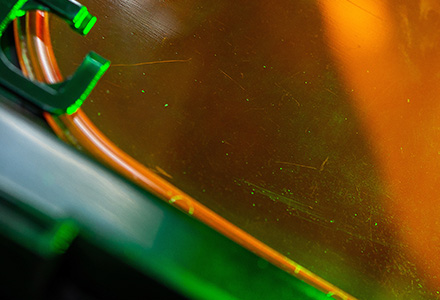

White substrate for ceramic circuit board. Defects and dust particles on the inspected surface with a white background are usually difficult to be detected. However, the difference can be clearly seen from certain angles of advanced model MK2. Suitable for industries in clean rooms that have strict requirements on the size and quantity of dust in the air.

Compared to the current Japanese brand inspection lamps which only have a circular area collimated detection light source with a diameter slightly larger than 2.5 cm, our MK2 can still provide a uniformly collimated large area light field even on a 20x20cm workpiece.